Head control menu

Mar 18, 2022 Editor: admin

When you click the right button of a track ball or click the <head control> command button, the pop-up menu appears on the screen. When you select the item to be executed from this pop-up menu, the system executes the corresponding operation.Warning: when you select an item form the pop-up menu, the axes move. Before selecting an item, be sure to check to see if there is no one who operates the inside of the machine. To avoid a risk of injury, do not put your hands inside the machine nor move your face or head close the machine while the machine is operationg.

Laser image display:

This command allows you to check the laser condition.

If a laser error frequently occurs or after you clean the laser head, perform this command to check the laser condition.

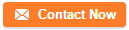

When you select the <control> command from the menu bar, the <head> command and then the <laser control> command in this order, the "laser control" screen appears.

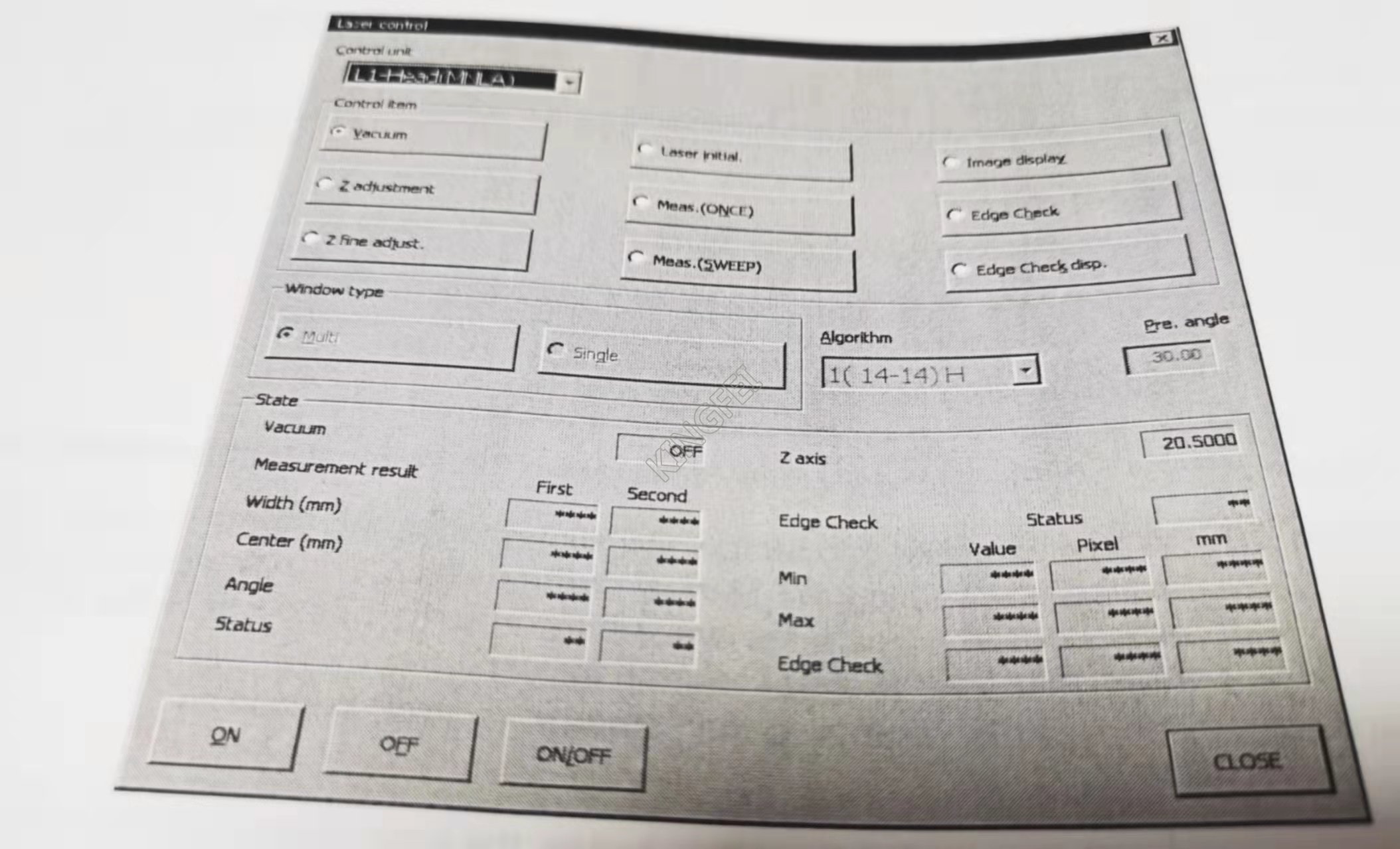

1) Image display

The system displays the image data of the laser sensor of the head selected in the "Control unit" edit box.

When the control item<Image display> is pushed, click the <EXEC> button or press the F3 key.

Check to see if the laser level is 70 or higher and displayed uniformly over the screen.

If you find any point whose level decreases abruptly or whose level is extremely low(65 or lower), clean the laser sensor surface.

-Laser level: indicates the brightness obtained when the photoreceptor receives light emitted from the phototransmitter within the range from 0 (darkest) to 255 (brightest). Therefore, if the laser sensor is stained, the level is lowered.

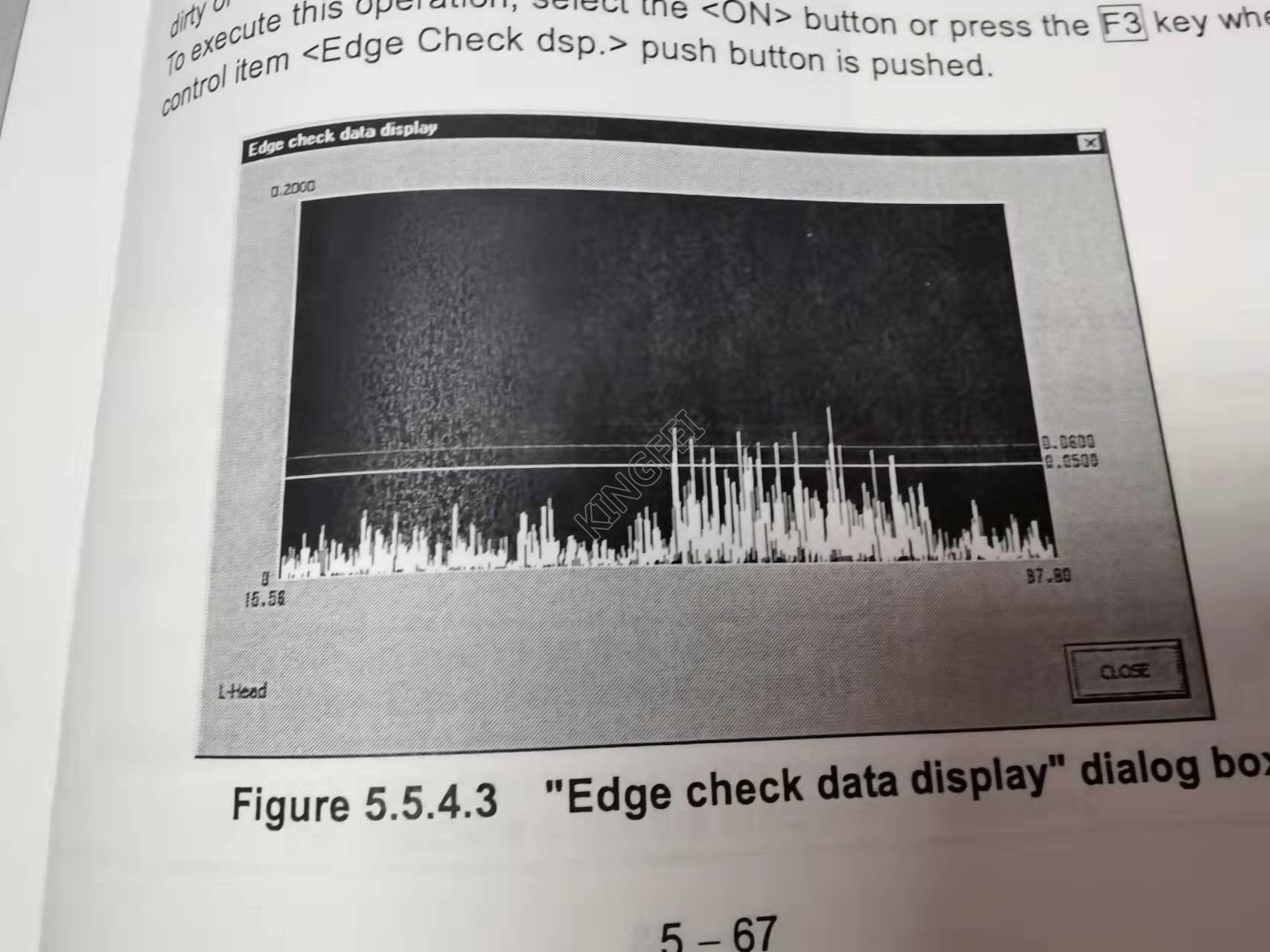

2) Edge Check dsp. (display)

This item checks to see if the entire laser sensor edge of the selected head gets dirty or dusty, then displays the check result data.

To execute this operation, select the <ON> button or press the F3 key when the control item<Edge Check dsp.> push button is pushed.

The edge check is the function that checks the laser sensor under the similar conditions with those for checking a component, and it can judge correctly whether the laser sensor functions well or not: this cannot be judged with the image check function. The value of the edge check result is represented with a nondimensional value, and if this value of any point exceeds 0.06, the system cannot center a component stably when the edge face of the component is located at this point. If the value exceeds 0.06, clean the sensor.